Intelligent Automation

High-volume laundry operations are revolutionized by Intelligent Automation and the Internet of Things (IoT). Sea-lion has developed an advanced portfolio of devices that enable seamless, automated transfer of laundry between machines—eliminating the need for manual handling. Powered by AI-driven SCADA control software, our systems optimize machinery performance, while CAD-designed layouts maximize space efficiency for a streamlined, productive workflow.

Soiled Sorting

Soiled sorting includes weight sensing loading conveyors into transport garment bags. Once loaded, the SCADA network control is able to monitor goods throughout the laundering process.

Overhead Monorails

Overhead monorails with transport garment bags are custom designed to take advantage of available space and store both soiled and clean linens during the laundering process. Intelligent routing controlled and monitored by the sophisticated SCADA control network keep accurate track of linen locations.

Elevator Transports & Lifts

Where space is at a premium, Sea-lion elevators, conveyors and lifts connect washer and dryer lines. For example, fuzzy logic in AI based system automation software determines exit points from tunnel washer either to extraction press or centrifugal extractor then transportation to appropriate dryer machine or storage location.

Sea-lion Engineering is capable of designing site specific solutions to solve logistics problems. We employ unique concepts that result in efficient movement of soiled and clean laundry.

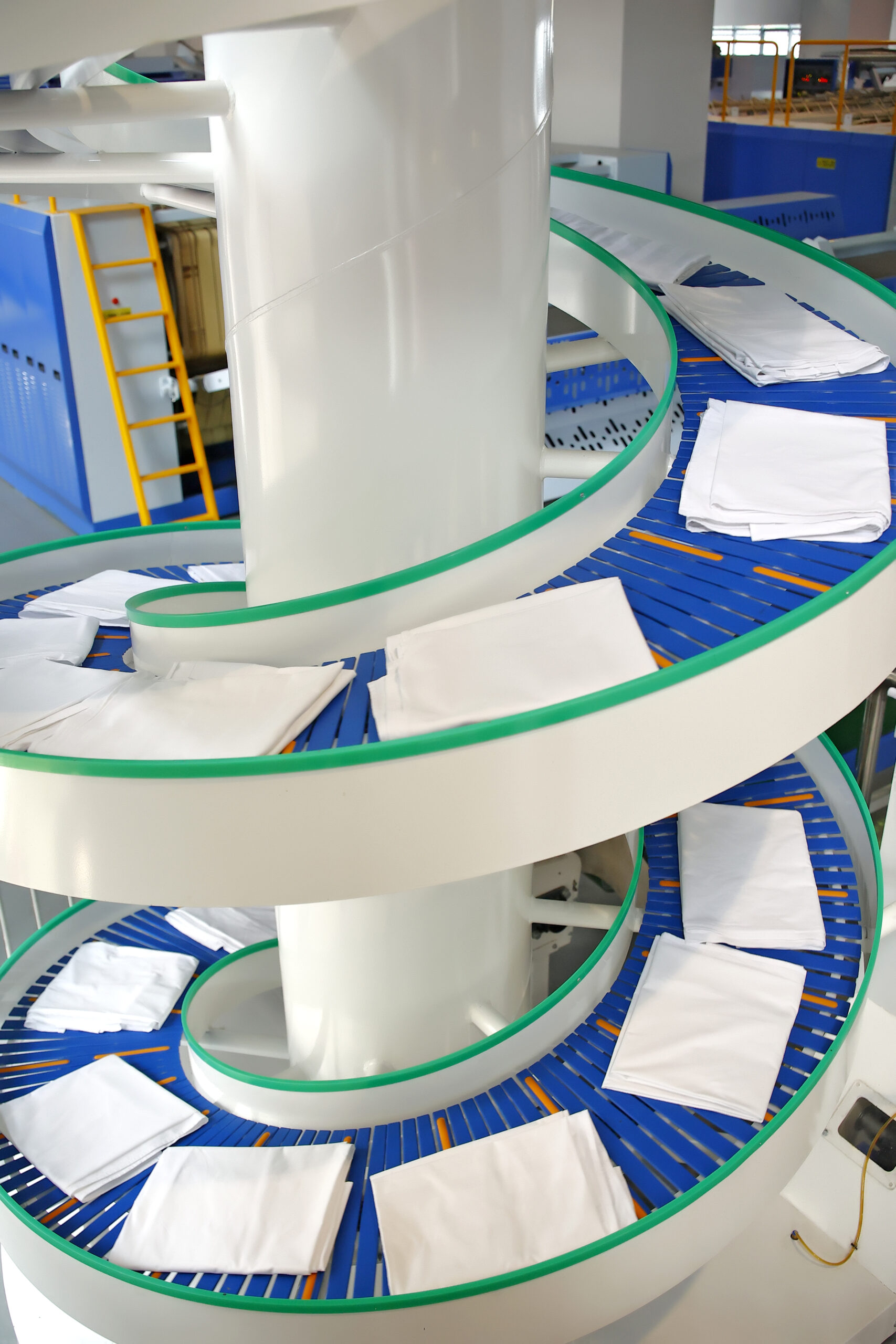

Shuttle & Conveyors

Shuttle and conveyor devices eliminate human interaction with the progress of laundry through the operation and constantly move goods from washing, drying and finishing stations.

Automation at Work

Intelligent Rail & Feeder System facilitates finishing line production bottlenecks by preparing and holding linens in a buffer zone to be processed. Fast, efficient, quality.